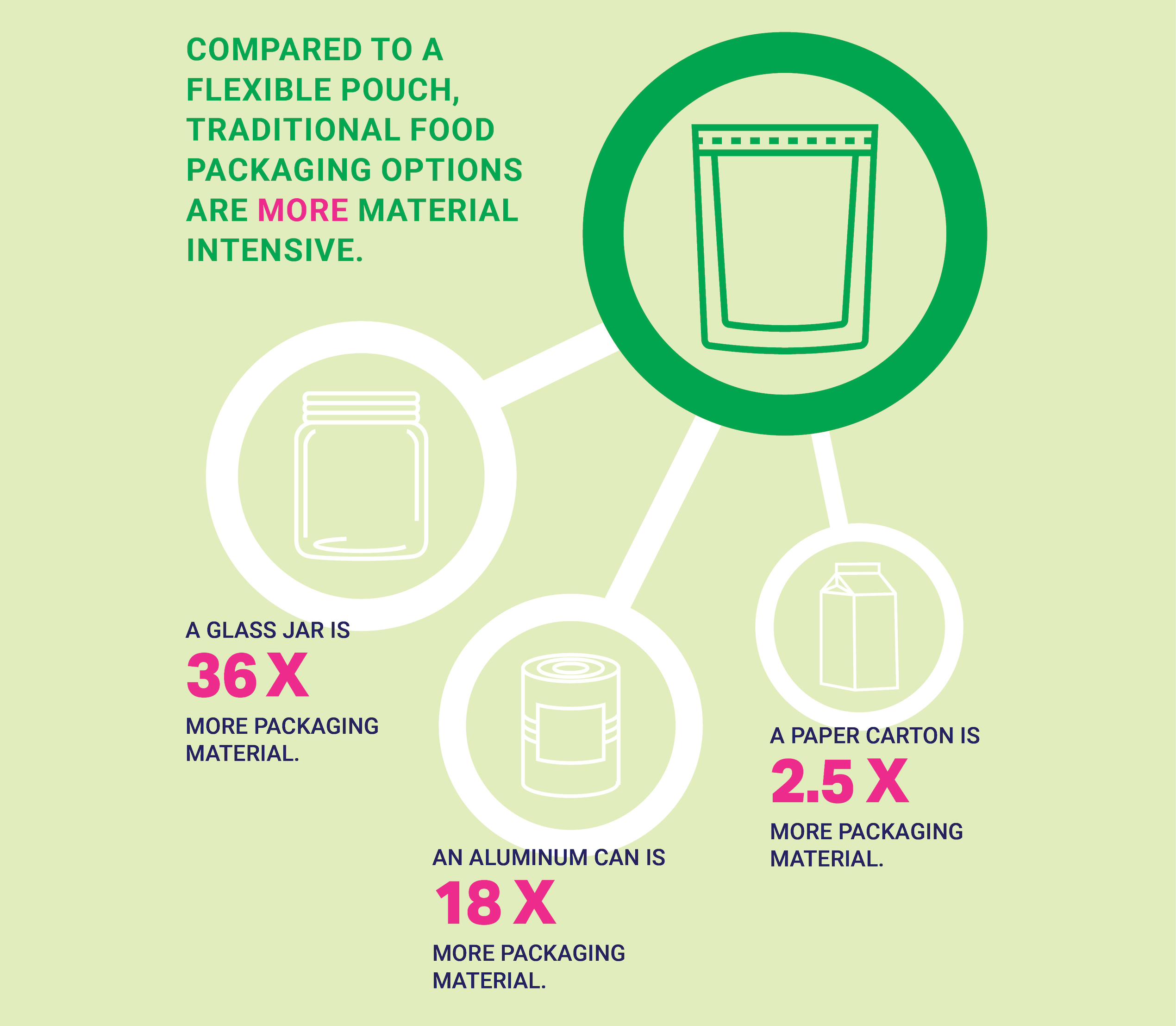

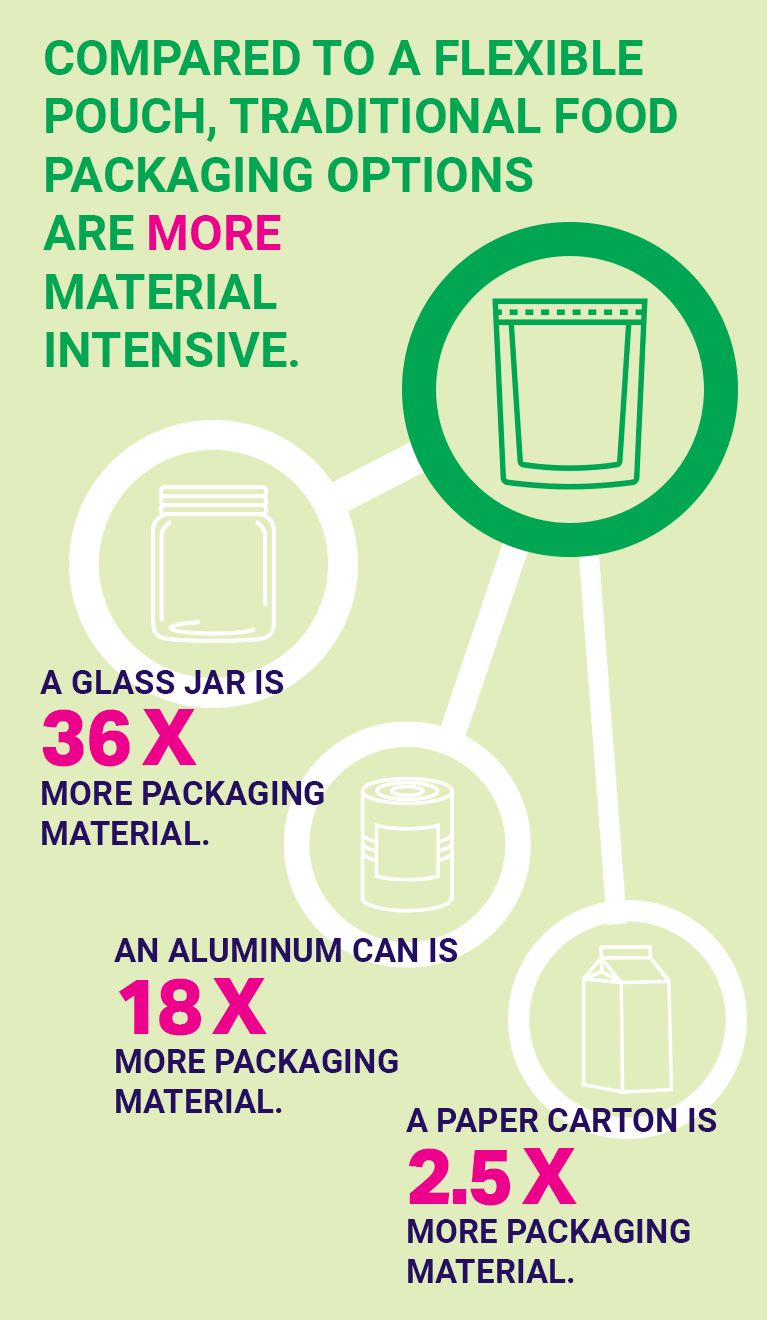

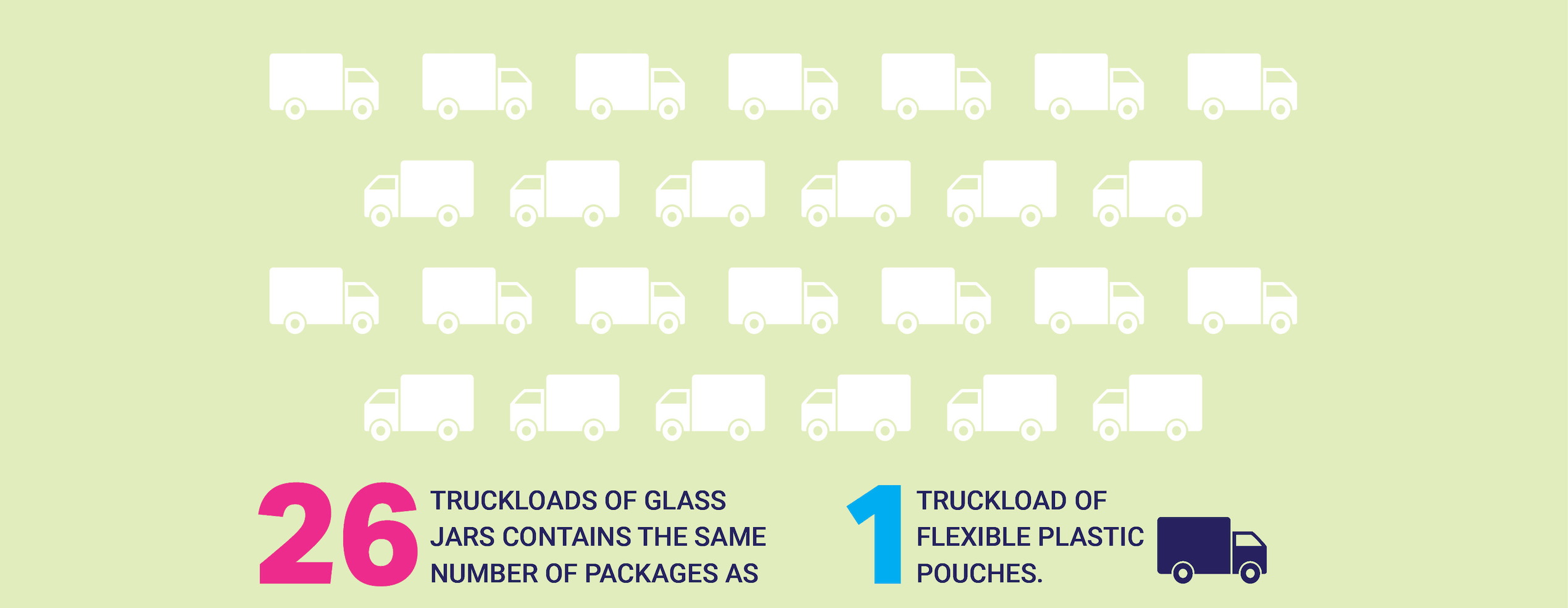

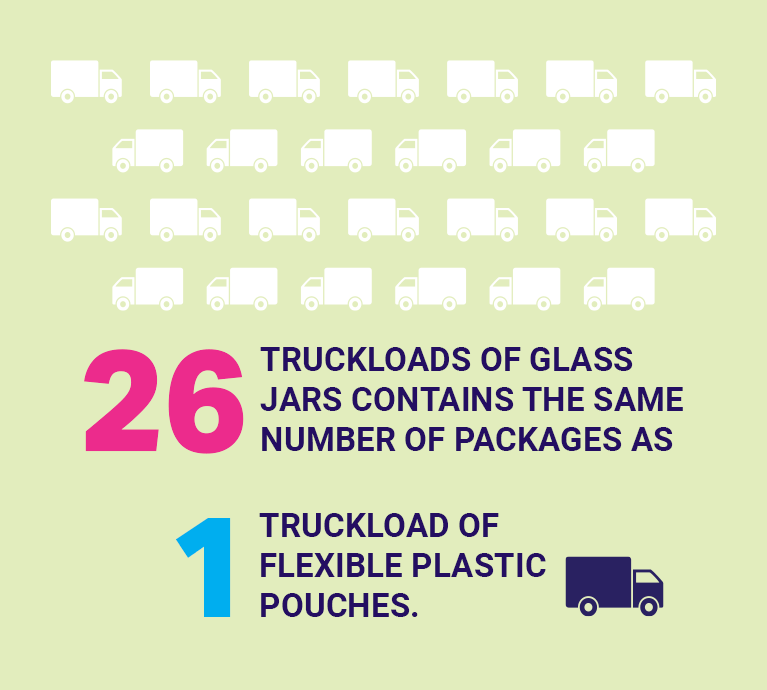

Traditional packaging options often involve bulky materials like glass, metal and rigid plastics. Flexible packaging utilizes lightweight materials, requiring fewer resources for production and transportation.

Flexible packaging offers unparalleled versatility in design. Its adaptable nature allows for precise sizing and shaping – minimizing excess material usage.

Flexible packaging isn’t just better for the environment, it is better for the bottom line. Its superior barrier properties protect products from moisture, light and oxygen – extending shelf life and reducing the likelihood of spoilage.

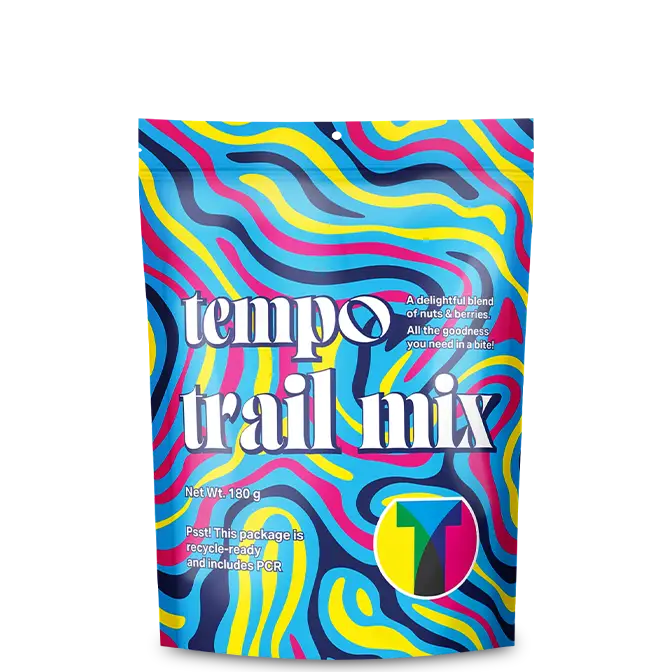

Meet consumer demand for convenience by offering lightweight, portable solutions that cater to an on-the-go lifestyle. Whether it is a resealable pouch for snacks, a stand-up pouch for sauces or individually wrapped bars, flexible packaging ensures hassle-free usability.

HarmonyPack solutions are designed for a circular economy. Aligned with the Golden Design Rules and Pre-Qualified for How2Recycle, transitioning to sustainability has never been simpler.

Backed by extensive research and development and over 50 years of experience in flexible plastics manufacturing, a HarmonyPack solution is available for almost every major retail category, including those that require high oxygen or moisture barriers. Since winning a sustainable packaging design award in 2015, HarmonyPack has been recognized multiple times as an innovative, recycle-ready option designed for circularity.

Transitioning to a new packaging structure can be a massive undertaking. This is why Tempo offers experienced experts to support you throughout the process, from optimizing design to attending machinability trials.

Ready to explore a greener future?

Community, Teamwork and Partnership are three of Tempo Flexible Packaging’s core values.

These values are also why we have focused efforts on building important relationships and are active members of the groups driving changes for the plastics industry:

The Association of Plastic Recyclers (APR) is the only North American organization focused exclusively on improving recycling for plastics. The APR leadership, along with its members, advocate large-scale improvements to our recycling systems.

Tempo Flexible Packaging is a member of the APR Film Committee and is well-versed in the APR Design Guide and packaging recognition programs.

The Sustainable Packaging Coalition (SPC) is a membership-based organization that believes in the power of industry to advance sustainable packaging, through education, collaboration and action. The coalition has members from the entire packaging value chain and serves as an invaluable resource for guidance and resources to drive positive change.

Further, membership in the SPC is required to leverage How2Recycle, a labelling system intended to standardize disposal instructions. Major retailers in both the US and Canada now require packaging to feature a How2Recycle symbol. Tempo Flexible Packaging is very familiar with the H2R submission and approval process, and our sustainable HarmonyPack solutions are pre-qualified.

PCR (Post Consumer Recycled) materials offer a powerful combination of sustainability and functionality.

By utilizing PCR, we are not only reducing waste but also actively contributing to a circular economy. This helps minimize environmental impact while maximizing resource efficiency. Choosing PCR isn’t just a choice for today – it’s a commitment to a greener future where packaging meets environmental responsibility head-on.

Tempo is one of the first flexible manufacturers to offer PCR options that are safe for food contact. Extruded on-site in our GFSI food safe facility, we are leading the industry in sustainable solutions.

Curious about PCR for your packaging?